تجهیزات بازیافت پودری

اگر به دنبال خرید یا تعمیر تجهیزات بازیافت پودری هستید، گروه صنعتی فن آوران با تجربه چندین و چند ساله خود در این زمینه میتواند به شما کمک کند. در این صفحه میخواهیم به طور کامل سیستمهای بازیافت پودر را معرفی کنیم و فرایند بازیافت رنگ پودری را توضیح دهیم. با ما همراه شوید.

برای آشنایی با تجهیزات بازیافت پودر، پیشنهاد میکنیم این توضیحات را بخوانید و در صورتی که هرگونه سوالی درمورد راه اندازی خط رنگ پودر، خرید تجهیزات بازیافت پودری و یا فرایند بازیابی رنگ پودری داشتید، با شماره تلفنهای درج شده در وب سایت تماس حاصل فرمایید.

منظور از بازیافت رنگ پودری چیست؟

وقتی از سیستمهای پاشش رنگ الکترواستاتیک استفاده میکنید، متوجه میشوید که بخشی از پودر رنگ روی قطعه قرار نمیگیرد. به این معنا که در خط تولید، مقداری از پودر رنگی که از تپانچه پاشیده میشود، مستقیماً به قطعه جذب نشده و در عمل به هدر میرود. البته این میزان هدررفت – که در ادامه توضیح خواهیم داد چگونه از این اتفاق جلوگیری کنیم – چندان زیاد نیست. اما به هر حال میتواند در هزینههای مواد مصرفی تاثیر بگذارد.

به طور کلی، در هر بار رنگ آمیزی قطعات، حدود 30 الی 90 درصد از رنگ پودری که از تپانچه خارج میشود، روی قطعه مینشنید. یعنی در بعضی از شرایط مقدار هدررفت رنگ پودری تنها 10 درصد است که میتواند به راحتی نادیده گرفته شود. اما در شرایط دیگر که حدود 70 درصد از رنگ پاشیده شده از تپانچه، برای رنگ آمیزی قطعه مصرف نمیشود و به هدر میرود، باید فکر دیگری کرد.

اینجاست که مفهوم بازیافت رنگ پودری مطرح میشود. اگر بشود این مقدار رنگ پودری که بیش از حد لازم پاشش میشود را به نوعی جمع آوری و دوباره استفاده کرد، نه تنها در هزینهها صرفه جویی میشود بلکه کمک بزرگی به محیط زیست خواهد کرد. یکی از ویژگیهای مثبت سیستمهای پاشش الکترواستاتیک و به طور کلی خط رنگ پودری همین است که میتوان بازیافت رنگ روی آن اعمال کرد. اما این اتفاق چگونه میافتد؟ توضیح خواهیم داد.

فرایند بازیابی رنگ پودری چگونه اتفاق میافتد؟

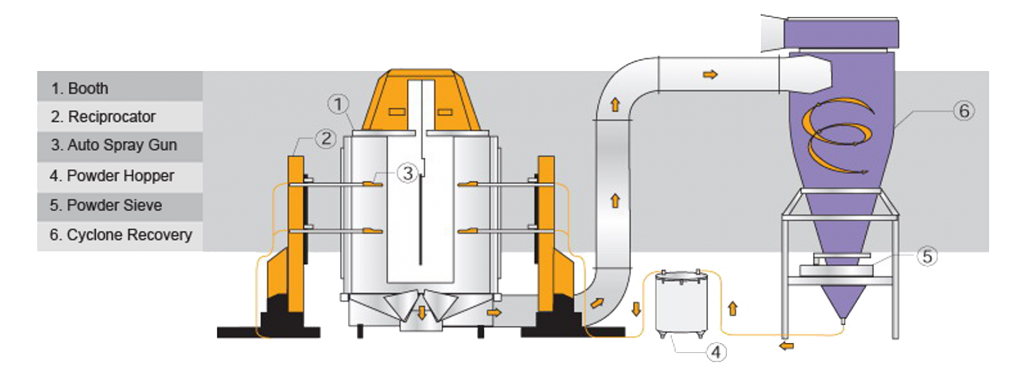

در یک نگاه کلی مکانیزم عملکرد سیستمهای بازیافت رنگ پودری به این صورت است که رنگهای اضافی ریخته شده بر روی سطوحی به غیر از قطعه مورد نظر، توسط فیلترهای مکندهای به داخل یک مخزن هدایت میشوند. به این طریق رنگی که در حالت عادی از دست میرفت، داخل فضایی نگهداری میشود تا برای دفعات بعدی مجدداً استفاده گردد. البته قبل از اینکه این رنگ دوباره به خوراک دستگاه پاشش تزریق شود، جداسازی احتمالی ناخالصی از آن صورت میگیرد.

اما فرایند بازیابی رنگ پودری را میتوان به دو دسته کلی تقسیم کرد. روش اول برای جمع آوری و بازیافت پودر استفاده از سایکلونها است. استفاده از فیلترها هم به عنوان دومین روش بازیافت رنگ پودری شناخته میشود. با اینکه هرکدام از این روشها فرایند خاص خودشان را دارند اما گاهی در یک خط رنگ، از هر دو روش استفاده میشود.

روش سایکلون و فیلتر هرکدام تفاوتها و مزایایی نسبت به دیگری دارند اما تا حدودی چرخه انجام آنها یکی است. در هر دو روش، پودری که از فضای داخلی کابین خارج میشود با استفاده از مکندههای مخصوصی، به یک مخزن مکش میشود. این مخلوط هوا و پودر در حین عبور از مونوسایلکون و یا مجموعه فیلتر، از همدیگر جدا میشوند. در نتیجه یک هوای عاری از پودر از فیلتر مخصوص خارج شده و پودر باقی مانده در مونوسایکلون و مجموعه فیلتر هم در مخزنی جمعآوری خواهد شد.

در این مرحله پودر موجود در مخزن الک میشود تا با جداسازی ناخالصیها از آن، امکان استفاده مجدد از آن به وجود بیاید. این مراحل بسته به بزرگی یا کوچکی خطوط رنگ ممکن است تا حدی متفاوت باشد. به طور مثال در خطوط رنگ با کابینهای کوچک، از سیستم فیلتر کارتریج مستقیم استفاده میکنیم که در ادامه روش کار آن را توضیح خواهیم داد.

فیلتر کارتریج مستقیم چیست و چه مزیتی دارد؟

در سیستمی که از فیلتر کارتریج مستقیم استفاده میشود، بسته به میزان پاشش پودر و حجم کابین، تعداد مشخصی فیلتر مستقیماً به کابین متصل خواهند شد. به این ترتیب عملیات مکش پودر از همان فضای داخلی کابین صورت میگیرد. با راه اندازی چنین سیستمی پودرهای جمع آوری شده توسط مکندهها، در قسمت پایین سیستم، درون مخزنی جمع آوری میشوند.

سیستم فیلتر کارتریج در مقایسه با سایکلونهای متداول، کارایی بالاتری دارد. چرا که عملیات را به صورت مستقیم انجام میدهد و همچنین کیفیت بازیافت پودر بسیار بهتر است. به علاوه نصب چنین سیستمی فضای کمتری را اشغال میکند. پس اگر از نظر فضا در کارگاه یا کارخانه خود با محدودیت رو به رو هستید، پیشنهاد ما راه اندازی سیستم بازیافت رنگ پودری به روش فیلتر کارتریج مستقیم است.

ما در گروه صنعتی فن آوران تمامی تجهیزات بازیافت پودری را فراهم میکنیم و پشتیبانی و نگهداری از آنها را نیز ارائه میدهیم. برای کسب اطلاعات بیشتر درباره چگونگی راه اندازی و یا استفاده از خدمات مربوطه، با همکاران ما تماس بگیرید.

معرفی تجهیزات بازیافت پودری

با توجه به اینکه بسیاری از تجهیزات بازیافت پودر مواد مصرفی دارند و یا باید طی دورههای مشخصی سرویس شوند، پیشنهاد میکنیم با عملکرد کلی این قطعات آشنا باشید. در ادامه علاوه بر توضیح نقش هرکدام از تجهیزات بازیافت پودری در این فرایند، مشخصات فنی و مزایای آنها را نیز عنوان خواهیم کرد.

سیستم الک پودر

یکی از اصلی دردسرهایی که مصرف کنندگان دستگاههای رنگپاش پودری با آن دست و پنجه نرم میکنند، بحث هدررفت رنگ است. اینکه ذرات پودر در بسیاری از شرایط روی قطعه جذب نمیشود و در فرایند اصلی، امکان جلوگیری از این اتفاق وجود ندارد. اینجاست که دستگاههای بازیافت رنگ پودری وارد میدان میشوند. یکی از مهمترین بخشهای این دستگاه هم، سیستم الک پودر است.

در واقع پودرهایی که در حین عملیات پاشش، باردار نشدهاند یا به هر دلیلی روی قطعه قرار نگرفتهاند، در سیستم بازیافت در سایکلون جمع آوری میشوند. اما به طور مستقیم نمیتوان مجدداً از این پودرهای جمع آوری شده استفاده کرد. به همین دلیل است که به سیستم الک پودر نیاز پیدا میکنیم.

در حجم بالای رنگ، دستگاه الک ویبره کمک میکند تا پودرهای رنگ اضافی، بهینهسازی شوند و دوباره به فرایند اصلی خط رنگ پودری برگردند. این دستگاه علاوه بر اینکه در هزینهها صرفه جویی میکند، این اطمینان را میدهد که رنگ پودری یکدست و بدون ناخالصی وارد سیستم شود.

مشخصات فنی و مزایای دستگاه الک ویبره

اگر قصد راه اندازی خط رنگ پودری استاتیک را دارید، گروه صنعتی فن آوران بهترین تجهیزات بازیافت پودری را در اختیار شما میگذارید. دستگاه الک ویبرهای که از این مجموعه تهیه میکنید قابلیت الک کردن 20 کیلوگرم پودر رنگ را در کمتر از 4 دقیقه دارد. این توانایی باعث میشود که کار تولید با سرعت بالا انجام پذیرد و اختلالی در فرایند اصلی خط رنگ ایجاد نشود.

این دستگاه امکان استفاده از ویبراتور پنوماتیک ایتالیایی را بدون نیاز به انرژی برق دارد. همچنین میتوانید بسته به نیاز خود سرعت عمل ویبره کردن را تنظیم و کنترل نمایید. همچنین این دستگاه امکان نصب دائمی در سیستمهای تمام اتوماتیک را دارد.

از مزایای دستگاه الک ویبره میتوان به یکسال گارانتی معتبر آن اشاره کرد به علاوه قیمت بسیار مناسبی که گروه صنعتی فناوران در اختیار شما گذاشته است. به طور کلی استفاده از این دستگاه میتواند از اتلاف رنگ جلوگیری کرده و در وقت و نیروی انسانی صرفه جویی چشمگیری کند.

پادر سنتر

قطعه دیگری که در بین تجهیزات بازیافت پودری نقش بسیار مهمی را بازی میکند، سیستم پادر سنتر است. هدف از نصب و استفاده از این سیستم در خط رنگ پودری، ساده کردن انتقال پودر سیال شده به نوک تپانچههاست. همچنین پادرسنتر این اطمینان را ایجاد میکند که حجم و کیفیت فلودایز تضمین شود. این ویژگی در روشهای متداول و معمولی وجود ندارد.

توجیه اصلی در جایگزین نمودن این سیستم با یک مخزن مرکزی پودر، بهره گیری از چندین روش فلودایز نمودن پودر و تضمین انتقال پودر در یک سیستم بسته مجهز به الک ترانسفر و مخزن اصلی پودر است تا کمترین زمان و هزینه صرف نظارت بر عملکرد سیستم پاشش گردد.

مزیت اصلی این دستگاه در واقع همین بالا بردن بهره وری خط رنگ پودری است. علاوه بر این با نصب سیستم پادرسنتر میتوانید شاهد کاهش زمان چشمگیر در فرایند و کاهش هزینهها باشید. اما به طور کلی وظیفه سیستم مدیریت پودر یا همان پادر سنتر بعنوان قلب خط پاشش پودری، ایجاد فلودایزینگ مناسب برای پودر رنگ ، جهت ارسال پودر به نوک تپانچهها است. برای هدایت رنگ، شما نیاز به یک سیستم فلودایزینگ کامل دارید.

در ساخت و طراحی پادر سنتر و جهت حصول اطمینان از فلودایزینگ کامل، استفاده از 2 مرحله فلودایز همزمان به همراه ویبراتور پیش بینی شده است .مرحله اول فلودایز، استفاده از صفحه فلوایز و باد ورودی از زیر مخزن اصلی است که در سایر دستگاههای پاشش نیز بطور متداول استفاده میشود. سیستم فلودایزینگ تکمیلی، استفاده از سطوحی متخلخل است که سبب فلوایزینگ بهتر در داخل مخزن میشود.