ربات پاشش پودری

اگر به فکر راه اندازی خط رنگ پودری هستید، یکی از تجهیزات مورد نیاز شما، ربات پاشش پودری است. رباتهای پاشش برای ایجاد یک پوشش یکنواخت روی سطوح استفاده میشوند. اگر قصد خرید ربات پاشش پودری را دارید اما از جزئیات این دستگاه بی اطلاع هستید، پیشنهاد میکنیم توضیحات زیر را حتماً بخوانید.

ربات پاشش پودری چیست و چه کاربردی دارد؟

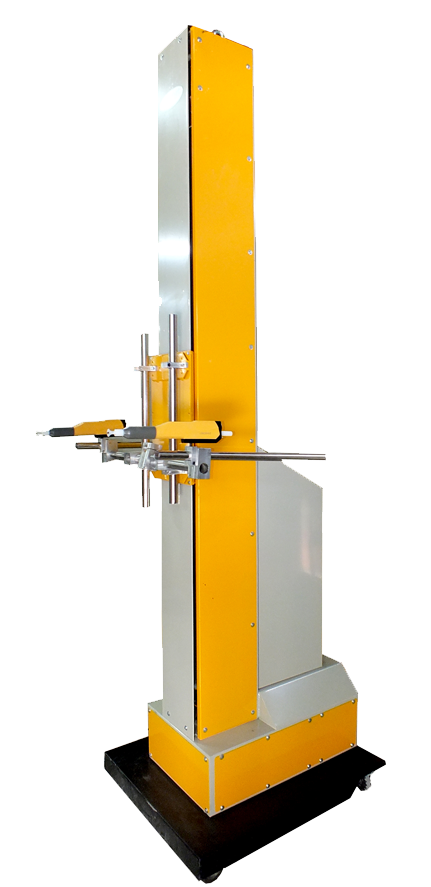

برای اینکه حرکت منظم و ملایم تپانچهها در سرعتها و مسافتهای مختلف (استروک) توسط کاربر قابل کنترل باشد، از ربات پاشش پودری استفاده میکنیم. ما در گروه صنعتی فن آوران به چند دلیل به فروش ربات پاشش پودری ELCOAT میپردازیم. این رباتهای پاشش امکانی به شما میدهند که بتوانید با برنامه ریزی دقیق، نحوه پاشش مطلوب و متناسب با قطعه را کنترل کنید.

همچنین با این نوع ربات پاشش پودری میتوانید کورس حرکتی ربات را به دقت کنترل نموده و در نتیجه اتلاف پودر را به حداقل برسانید. از نظر فنی، سیستم فرمان این رباتهای پاشش، به تجهیزات PLC مجهز است. به همین خاطر در صورت لزوم میتوان با افزایش دادن یا کاهش سرعت کانوایر، سرعت حرکت تپانچههای متصل به بازوهای ربات را هم به طور متناسبی تغییر داد.

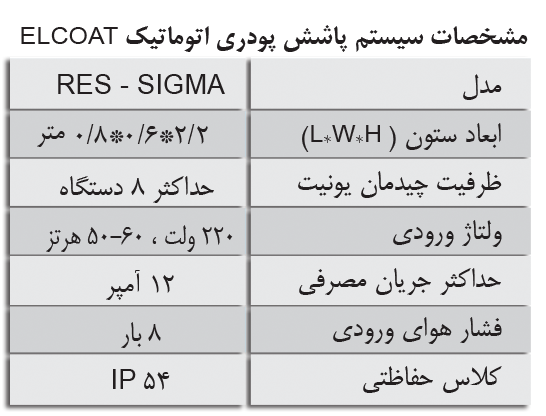

شما میتوانید مشخصات کامل ربات پاشش پودری ELCOAT را در جدول زیر ببینید. این سیستم میتواند بیشتر از 25 برنامه مختلف پاشش برای هر ربات را ذخیره سازی کند. به علاوه کلیه اقدامات حفاظتی برای ذخیره اطلاعات سیستم از قبل انجام شده است. به همین خاطر است که خرید ربات پاشش پودری از همه نظر توجیه پذیر خواهد بود.

معرفی رک اتوماتیک پاشش پودری

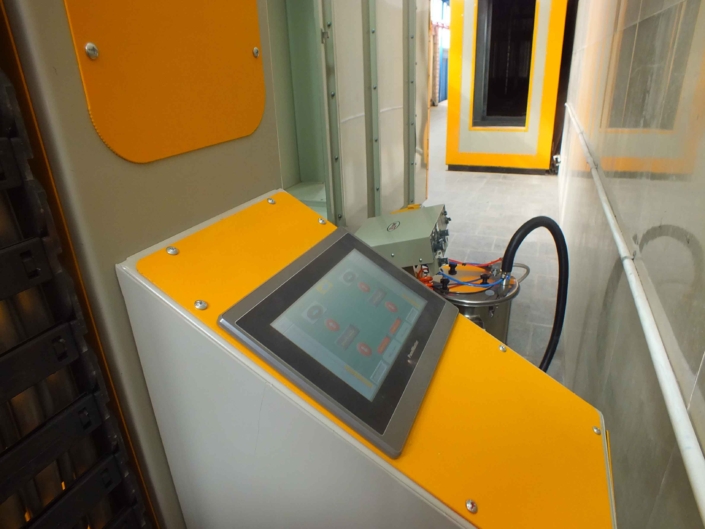

دستگاه دیگری که جزو تجهیزات خط پودر رنگی به حساب میآید، رک اتوماتیک است. این دستگاه میتواند به طور همزمان برای حداکثر 7 دستگاه کار کند و از این نظر گزینه خوبی برای واحدهای بزرگ صنعتی است. رک اتوماتیک برند ELcoat، علاوه بر مجهز بودن به سیستم مرکزی کنترل هوای ورودی و هوای فلودایز، برق و اتصالات پنوماتیک، یک صفحه نمایش مجهز به PLC دارد. از طریق این صفحه میتوان فعالیت رباتها و تنظیمات مربوط به آنها را کنترل کرد.

کار کردن با این دستگاه بسیار ساده است. به همین خاطر بعد از خرید ربات پاشش پودری ELcoat، دیگر نگران هزینه آموزش اپراتور نخواهید بود. گروه صنعتی فن آوران افتخار این را داشته است که مجموعه تکمیلی و پیشرفته این سیستم در اولین خط رنگ پودری عمودی ایران را راه اندازی کند که امکان پاشش همزمان 48 دستگاه پاشش پودری را دارد. توضیحات فنی درباره این دستگاه را میتوانید در جدول زیر مطالعه کنید.

فروش ربات پاشش پودری با بهترین قیمت و کیفیت

اگر شما هم قصد خرید ربات پاشش پودری یا رک اتوماتیک را دارید، میتوانید با همکاران ما تماس بگیرید تا علاوه بر استعلام قیمت ربات پاشش پودری و سایر تجهیزات، برای راه اندازی و استفاده از این سیستم هم به شما مشاوره تخصصی بدهند. گروه صنعتی فن آوران طی سالها تجربه فروش ربات پاشش پودری و سایر تجهیزات خط رنگ پودری، یکی از معتبرترین شرکتها در این حوزه به حساب میآید.