Powder Coating Process

Powder coating is an increasingly popular method for providing a protective and/or decorative coating on metallic objects. Unlike liquid paints, a powder coat is a dry material that will not drip or run upon application. Powder coating is most commonly used on metals such as iron or steel.

The powder-coat process entails the application of electrostatically charged particles onto the surface of the substrate. In a typical powder-coating system, a feeder unit delivers the powder to an electrostatic gun. The feeder unit also controls the flow of powder to the gun. The gun emits the powder in the form of a diffused cloud. When combined with an electrical field charge provided by a low-amperage power unit, the charged particles seek out and adhere to the surface of the substrate.

Upon application of the coating, the next step in the powder-coating process is curing, which involves baking the workpiece in a specially designed oven. Curing results in the formation of a protective skin and promotes coating adhesion. In general, curing is performed at 400 F for approximately 20-30 minutes, although these parameters can vary based on the type of powder coating.

Surface pretreatment is also essential for achieving a successful powder-coating outcome. This normally entails the removal of grease, oil, dirt and other materials via chemical, physical or mechanical methods to clean the surface and promote coating adhesion. Pretreating the workpiece with chemical compounds can enhance the coating’s performance, durability and corrosion resistance.

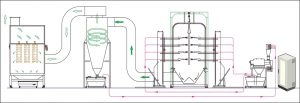

As shown in above schematic coating zone, there are 6 main equipment which are applied in automatic powder coating line. When the powder is negatively charged, it leaves the guns mounted on reciprocator’s arms and disperses in powder booth. The powder settles on part surface and the over sprayed powder is removed from booth area with help of a mono cyclone. The powder is recovered in a 2-stage recovery system including mono cyclone and after filter system.

The recovered powder is sent to the sieving machine and then charged to powder hopper. The fresh powder is mixed with the recovered one, and pumped to spray guns. The whole process is controlled in central control unit. The conveyor system and curing oven complete the powder coating plant. Based on the production capacity, the parameters for the best results are calculated and manufactured accordingly.

Pretreatment

During the preparation, the metal has to go through a cleaning process. This is to remove any foreign substances that will hinder the success of the coating process. A chemical is used to remove oil, lubricant or grease on the metal. Another method is blasting, which utilises a blasting medium to remove metal edges and serve as a finishing touch. Instead of subjecting the metal object to a grinding machine to remove edges or to polish, blasting is a more efficient and faster method.

Powder booth

The purpose of the powder booth in electrostatic spraying is to ensure that powder from the application device stays inside the booth. This then offers the opportunity to collect the over sprayed powder ,recover it and re-use. Elcoat powder booth, is designed and manufactured at high quality and a variety of sizes and configurations are available to suit any type of powder coating operation. Conveyor openings and length extensions are also available. Elcoat offers powder coating booths that provides high-performance and provides energy-efficient powder coating environments.

Powder Coating Spray

The electrostatic spray method is the most commonly used technique for applying powder coatings. This process involves charging powder particles electrically and spraying them onto a grounded part. The electric charge ensures that the powder adheres to the surface until it’s melted and fused into a smooth coating in the curing oven. This method is highly efficient, allowing for quick application and minimal waste since excess powder can be collected and reused.

Elcoat utilizes this method for a variety of applications, offering excellent coverage, uniform thickness, and a vast selection of colors and finishes. Suitable for metal substrates like steel and aluminum, it’s a versatile choice for everything from automotive parts to household appliances.

By collecting the powder, which passes by the job, and filtering it, the efficiency of the process can be increased to 95-98% material usage.

Powder Curing

The final part of powder coating process is known as curing. The surface of the metal, or the substrate, is already coated, and the coating is in a powdered form, which means it is ready for the finishing touches. Curing is designed to make a powder adhere to the metal so firmly that it will last for years. It also turns the powder into a smooth substance that looks like it has been painted on.

The curing process entails applying heat to the coating at a specific temperature so that it will achieve the final objective of the powder coating method. The coating should not be subject to direct heating, meaning that heating elements should not touch the powder coating, as that would simply burn it.

The items being processed need to be placed inside an oven, which contains heating coils. The heating coil will direct infrared heat to the whole coated object, a process known as convection heating. Convection heating lets the heat travel to the substance without direct contact so that the heating coils do not touch the coated object. In simple terms, it is just like a person inside a sauna room!

The oven is set to the required temperature, and there should be a timer to control the time of curing. With the correct amount of time and temperature, the powder coating will form a solid film of plastic wrap around the metal.